In the oil drilling sector, polyurethane is used for several purposes due to its exceptional mechanical properties, durability, and chemical resistance. In the most demanding drilling applications, polyurethane is unmatched in the oil drilling industry.

-Example of a coiled tubing stripper rubber, which removed drilling mud and fluid from the drill pipe as it is pulled out of the bore-hole

Downhole Tools:

Polyurethane is used to manufacture downhole tools, such as drill bits, stabilizers, and reamers. These tools are subject to extreme conditions, such as high pressure, high temperature, and abrasive environments. Polyurethane has excellent wear resistance and high-temperature stability, making it an ideal material for manufacturing these tools. Additionally, polyurethane is highly resilient and has good shock-absorbing properties, which help to reduce the wear and tear of the drilling equipment.

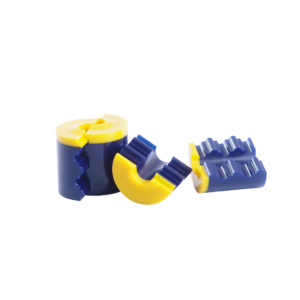

Centralizers:

Polyurethane is used to manufacture centralizers that are used to keep the casing pipe centered in the borehole during drilling. Centralizers are critical components in the drilling process, as they help to prevent the casing from becoming stuck and facilitate proper cementing. Polyurethane centralizers offer superior wear resistance, high-temperature stability, and excellent chemical resistance, making them ideal for use in harsh drilling environments.

Pipe Protection:

Polyurethane is used to protect pipes from corrosion and mechanical damage during drilling. Polyurethane coatings provide a durable and long-lasting protective layer that resists abrasion and impact. Additionally, polyurethane coatings have excellent chemical resistance, making them ideal for use in pipelines that transport corrosive fluids.

Fracturing:

Polyurethane is used in hydraulic fracturing operations to create seals and barriers that prevent the fracturing fluid from escaping into the surrounding rock formations. Polyurethane foams are injected into the wellbore to create a barrier that helps to direct the fracturing fluid to the targeted rock formations. Additionally, polyurethane is used to manufacture proppants, which are small particles that are mixed with the fracturing fluid to hold open the fractures in the rock and allow the oil and gas to flow.

Polyurethane is a versatile material that has numerous applications in the oil and gas industry. In oil drilling, it is used to manufacture downhole tools, centralizers, pipe protection, and in hydraulic fracturing operations. Polyurethane offers superior wear resistance, high-temperature stability, excellent chemical resistance, and good shock-absorbing properties, making it an ideal material for use in harsh drilling environments. The use of polyurethane in oil drilling has led to improved drilling efficiency, reduced downtime, and increased safety, making it an essential material in the oil and gas industry.