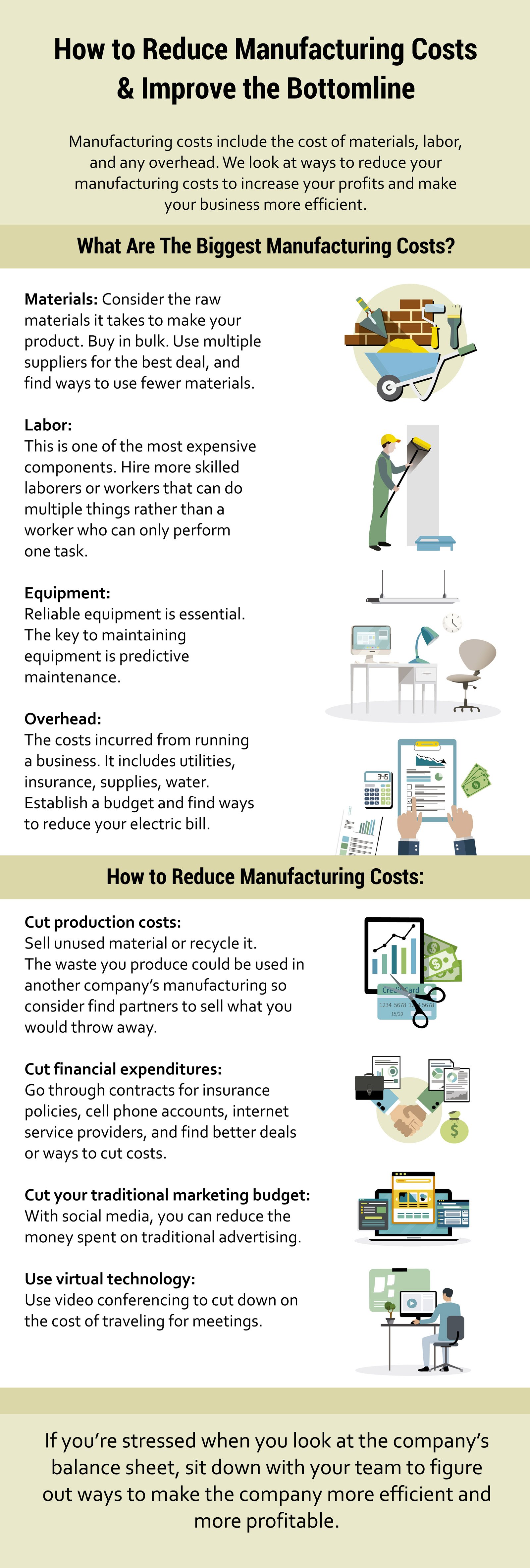

Whether you’re a manager or high-level executive in a company, one way to dramatically reduce your company’s expenditures is to reduce manufacturing costs. Stated by TPC Inc, manufacturing costs include the cost of materials, labor, and any overhead associated with the manufacturing process, such as equipment and maintenance.

In this article, we look at ways to reduce your manufacturing costs to increase your profits and make your business more efficient.

What Are The Biggest Manufacturing Costs?

We’ve already touched on the main costs associated with manufacturing, but let’s go into detail on each one and how to reduce the costs.

Materials

Materials are the physical raw materials you purchase to make your product. Since raw material costs fluctuate, it’s wise to look for ways to find these items at a lower price, and one way to do that is to take advantage of buying these items in bulk when you can.

Also, try not to rely on one source for your raw materials and instead use multiple suppliers so you can always get the best deal. If you have a particular supplier you like dealing with but can find the materials elsewhere cheaper, maybe your primary supplier will be willing to cut you a deal or match the price to keep your business.

Another way to cut down on material costs is to look for ways to use fewer materials in the products you make. This may take some innovation, but as your product advances in how it’s produced, you can find ways to use less to achieve the same goal.

Labor

Labor is one of the most expensive components in the manufacturing process, so it’s a good idea to make your labor force as efficient as possible to get the most bang for your buck.

To improve worker efficiency, try hiring more skilled laborers. Skilled laborers cost more, but they are better at getting work done and make fewer mistakes, which means you get a better product with less waste.

Also, look at ways to improve your workforce via training so they can develop new skills and become more valuable to the company. Having a worker that can do several things is cheaper and more efficient than a worker who can only perform one task.

Equipment

Having reliable equipment is essential to the manufacturing process, and the last thing you need is downtime due to broken machines. The key to maintaining equipment is to engage in predictive maintenance. When you purchase a machine, the manufacturer usually has a maintenance schedule you should follow, but in addition to that, you should plan on implementing a predictive maintenance schedule to ensure your machines are in tip-top shape.

Predictive maintenance takes care of minor problems before they turn into ones that bring the whole system to a halt.

Predictive maintenance works by monitoring the systems for parts that may be failing and taking care of them. Instead of preventative maintenance where you replace parts based on how old they are, you replace them by predicting when they will fail, which means you can run your machines longer than if you used a traditional maintenance plan.

Always be on the lookout for new equipment that runs more efficiently than your old systems and finds ways to replace them.

Overhead

Overhead are the costs incurred from running your manufacturing plant and include your utilities, insurance, supplies, water, etc. Be proactive here and look for ways to reduce your electric bill by installing LED lighting in places where it makes sense, and stop printing everything out to reduce how much you spend on paper.

It’s helpful to establish a budget for these expenses and then stick to it by finding creative ways to lower your costs.

How to Reduce Manufacturing Costs

We already looked at ways to reduce the cost of your materials, your equipment, and your overhead; now we look at some other ways you can save money when making your products.

Cut Production Costs

No matter what you’re making, the process leaves you with waste or material you haven’t used. One way to cut your production costs is to look for ways to sell this unused material or recycle it.

Sometimes, the waste you produce will be used in another company’s manufacturing process, so look for ways to partner with others to sell what you’re probably throwing away.

Cut Financial Expenditures

Periodically go through items like insurance policies, cell phone accounts, internet service providers, etc., and look for better deals or ways to cut costs. Maybe you can save money by bundling your cell service with your internet package. The key is to examine everything and find ways you can cut these expenses because they do add up.

Cut Your Marketing Budget

Whether you’re making products for the general population or products for other commercial entities, you have to get the word out about what you’re selling, and that always meant advertising and sales.

Today, thanks to social media, you can cut down the amount of money you spend on a sales force and advertising by using digital marketing such as building email lists and using Facebook, Instagram, and other social media sites to let the world know what you’re making.

Use Virtual Technology

Do you have meetings you have to conduct regularly? If so, consider using technologies like FaceTime or video conferencing to cut down on the amount of traveling people have to do.

Make Smart Capital Investment Decisions

The key here is to be proactive in examining your current machinery and workflow and looking for ways where you can improve efficiency with new systems. A new machine may cost you $100,000, which is a lot, but if it saves you tens of thousands of dollars per year because it’s faster and does a better job, then it’s a wise purchase.

If you’re always stressed when you look at the company’s balance sheet, stop and sit down with your team to figure out a way to make the company more efficient, more profitable, by reducing your expenses. It may be tough, but if you get creative, it can be done.