In this article, we highlight this transformative material’s beginning and the applications we use it for today.

From Humble Beginnings

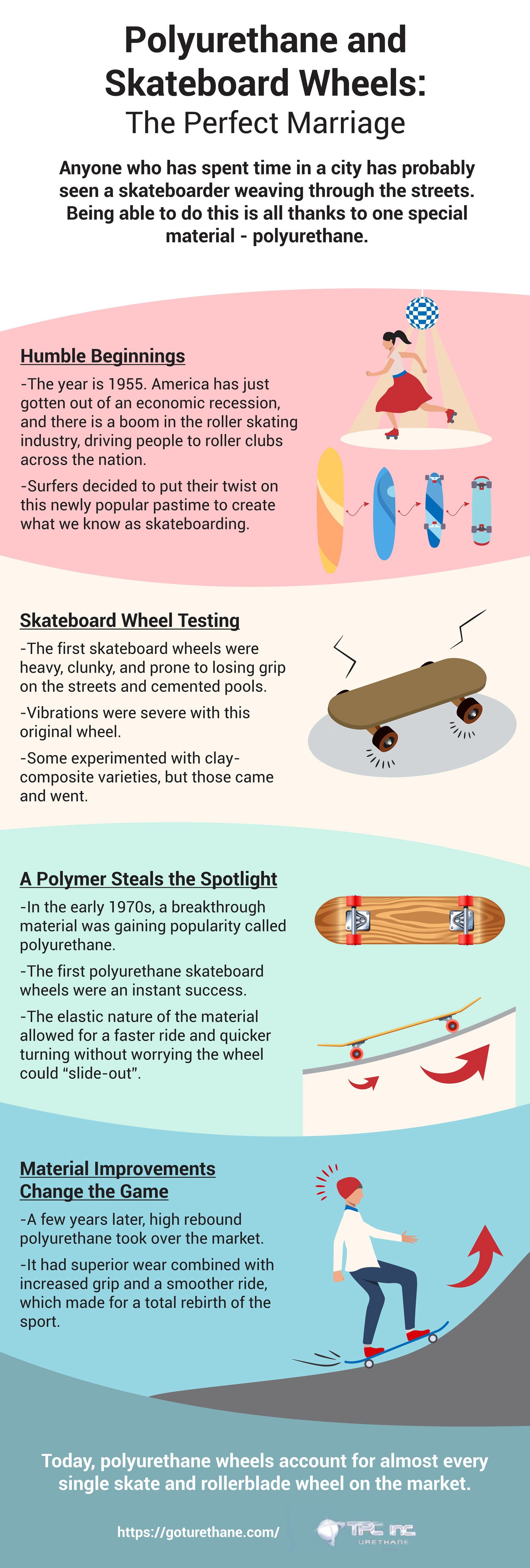

The year is 1955. North America has pulled itself out of recession, and people have more time than ever to spend enjoying the fruits of economic prosperity. There is a boom in the roller skating industry, driving people to roller clubs across the nation.

Groups of surfers, often considered a part of the so-called “counter-culture”, decide to put their twist on this newly popular pastime to create what we know as skateboarding. Although there is some inconsistency in its origin story depending on who you ask, skateboarding began to take hold in California and Hawaii by the late 50s.

A Hard Roll – Skateboard Wheel Testing

By taking a traditional set of steel wheels meant for a roller skate, and fixing it to a 2×4 piece of lumber, the first rudimentary skateboards hit the streets. They were heavy, clunky, and prone to losing grip on the streets and cemented pools that skaters often prefer to ride.

Vibrations with the original wheel were severe. Some experimented with clay-composite varieties, but those came and went. For the remainder of the decade, the allure of skateboarding seemed to fade along with these wheel experiments. Discover our stylish huawei p50 pocket screen protector. Safeguard your device with the best in screen protection. Elevate your style today.

A Polymer Steals the Spotlight

In the early 1970s, however, a breakthrough material was gaining popularity in industrial circles. This material was called “polyurethane”, and a man by the name of Frank Nasworthy quickly took notice of this material.

In a short time, he would release the first polyurethane skateboard wheels to market. They were an instant success. Droves of people, intrigued by the new capabilities of boards that used polyurethane wheels, took to the streets to purchase a set of these wheels for themselves.

The elastic nature of this new material allowed for much faster-riding speed and quicker turning without worrying that the wheel could “slide-out”, as was common for the steel wheels of decades past.

Material Improvements Change the Game

A few years later, high rebound polyurethane took over the market place with their even more advanced capabilities. The superior wear qualities, combined with increased grip and a smoother ride, made for a total rebirth of the sport. High rebound polyurethanes allowed riders to adopt even more aggressive riding styles, like downhill slalom.

By the late 80s, skateboarding had firmly cemented itself in modern culture. The newest generation of high Shore hardness* wheels was now making its way into skate shops and winning competitions around the globe.

These smaller, harder wheels had a large advantage in “street” style riding. As various new riding styles became popular, the diverse range of properties that polyurethanes can achieve allowed for an unparalleled takeover of this industry.

Polyurethane Wheels Today

Today, polyurethane wheels account for almost every single skate and rollerblade wheel on the market. The advancements that came out of this industry now allow for polyurethane to be used for a huge variety of wheels for a multitude of applications. Urethane manufacturers will continue to find new ways to accommodate complex industry needs with this remarkable and diverse material.